1. Mageneto introduction

The Mageneto special anode (MAGNETO special anodes) is a well-known international enterprise based in Holland. It specializes in the development, manufacture and sale of insoluble anodes for various applications of industrial electrochemistry, especially in the field of electroplating, to make the Maher Neto anode the most focused field. The titanium anode consists of an inert titanium substrate and a noble metal oxide active coating on the titanium substrate. In 1957, Dr. Henry Bill (DR.Henri Beer), inventor of the world's metal coated titanium anode, founded Maher Neto, and Maher Neto was the world's invention and earliest manufacturer of platinum titanium anode and precious metal oxide coated titanium anode.

In various fields of titanium anode application, Maher Neto has been focusing on the harsh special anodes for R & D and production applications. With its excellent product quality and leading titanium anode research and development capabilities, in the past few decades, Maher Neto has devoted himself to providing the most ideal anode for every application field, and has accumulated rich experience. The company designs, produces and supplies a large variety of anodes, which can be used in almost all kinds of electrochemical systems and processes. Maher Neto has established a high reputation in the field of special titanium anode. The brand of Maher Neto special anode has become the benchmark of industry technology and quality.

2. application fields

2.1 PCB electroplating:

---PCB DC copper plating process includes: VCP line, horizontal electroplating line, vertical Line plating.

---PCB pulse plating process; mainly used for high thickness diameter through hole plating (backplane, semiconductor test plate, etc.);

---PCB gold plating process;

2.2 electronic electroplating

- semiconductor device plating: coil to coil plating, contactor plating, lead frame plating, electropolishing, selective plating, etc.

- precious metal electroplating: gold plating, silver plating, palladium plating, rhodium plating, ruthenium plating, etc.

- - electroplating bath water treatment and metal recovery;

3. technical advantages

The 3.1 VCP special anode (Modified Selecta Ir MMO Coating) can bring better coating distribution and less copper consumption by PCB; the high efficient catalytic activity of the noble metal coating can better improve electroplating current efficiency, long anode life performance and low consumption of electroplating additives; Iridium oxide coating destroys organic additives during electrolysis. Maher Neto developed a proprietary anode coating for special requirements in this field to reduce the consumption of additives to a large reduction in the general iridium oxide coating anode. The actual running line data of Maher Neto statistics show that the additive of the special coating titanium anode of Maher Neto's special coating is the lowest insoluble Yang in the industry. Extremely.

The 3.2 titanium anode consists of an inert titanium matrix and a noble metal oxide coating on which the coating is coated. In the process of electroplating, this layer of noble metal oxide coating will be gradually consumed and the stable structure of the anode coating is destroyed and the performance will decline. In concrete practice, the consumption of additives is increased and the anode has one. The service life of the anode is characteristic of the anode itself, and the anode life is more than 1 years.

4. technical specification design:

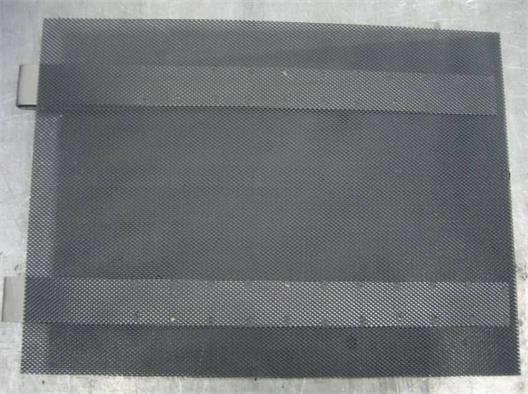

Net mesh of 4.1 reticulated anodes:

---Type one:Mesh (factor 2) L*W*B*A=6*3.5*1*1mm.

- Type two:Mesh (factor 2) L*W*B*A=12.5*6.5*2*2mm.

4.2 plate anode

- pure titanium plate with thickness of 2mm or 3mm for one-sided coating.

---Coating composition main components: IrO2/Ta2O5 mixed metal oxide coating, low additive consumption design

DongGuan Innovate Electronic Technology Copyright© 2018 粤ICP 19140739号

TEL:+86 0769 81209289 FAX:+86 0769 81209869 MOB:+86 13802380327 E-mail:taylor.innovate@outlook.com

BeiWang Road No.63, Zhongtan town, Donguan city Guangdong Province PRC